Introduction:

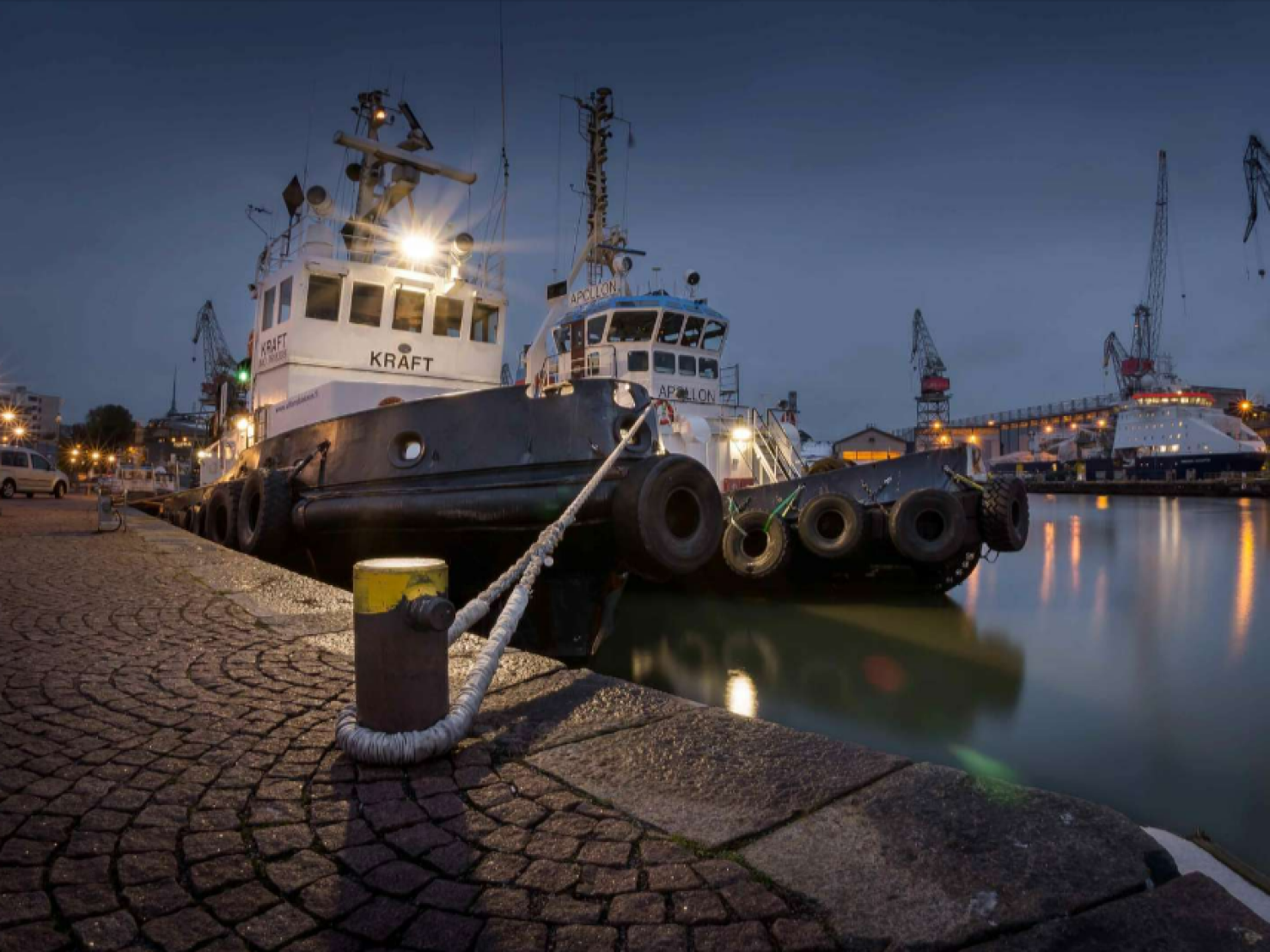

Efficient port and harbor operations rely on the smooth functioning of various components, including port infrastructure, vessels, and equipment. Among these components, port and harbor fenders play a vital role in minimizing maintenance costs and reducing operational downtime.

As Europe's largest rubber and polyurethane fender manufacturer, Bencros understands the significance of cost-effective solutions. In this comprehensive blog post, we delve into the intricate world of port and harbor fenders, highlighting their impact on reducing maintenance costs and maximizing operational productivity.

- Minimizing Structural Repairs:

Port infrastructure, such as quays, piers, and docks, is subject to constant stress and strain caused by vessel berthing. The impact forces generated during berthing can lead to structural damage, requiring costly repairs. Port and harbor fenders act as a protective barrier, absorbing and dissipating the energy of the impact, thereby minimizing the risk of structural damage. By reducing the need for frequent repairs and maintenance, fenders contribute to significant cost savings for port authorities.

- Extending Infrastructure Lifespan:

Port infrastructure represents a substantial investment for port authorities, and maximizing its lifespan is crucial. Port and harbor fenders play a key role in extending the lifespan of the infrastructure. By absorbing and distributing the energy of vessel impacts, fenders minimize the direct forces exerted on the structures. This protection helps prevent structural deterioration, including cracks, deformation, and wear, which can lead to more significant issues over time. By preserving the integrity of port infrastructure, fenders enable longer service life and reduce the need for premature replacements.

- Reducing Vessel Maintenance:

Vessel maintenance is a significant cost factor for ship owners and operators. The use of port and harbor fenders can help reduce vessel maintenance requirements. By providing a cushioning effect during berthing, fenders minimize the risk of hull damage, abrasion, and paint chipping caused by direct contact with the quayside or jetty. This protection extends the lifespan of vessel hulls and coatings, reducing the need for frequent repairs and repainting. As a result, ship owners can enjoy substantial savings in maintenance costs and improve their operational efficiency.

- Preventing Equipment Damage:

In addition to vessels and infrastructure, port and harbor operations involve the use of various equipment, such as cranes, loaders, and conveyors. The vibrations and shockwaves generated during vessel berthing can impact nearby equipment, leading to damage and operational disruptions. Port and harbor fenders help mitigate these risks by absorbing and dampening the impact forces. By minimizing the transmission of vibrations and shocks, fenders protect the nearby equipment, reducing the frequency of repairs and minimizing downtime.

- Streamlining Berthing Processes:

Efficient berthing processes contribute to reduced downtime and increased operational productivity. Port and harbor fenders facilitate streamlined berthing operations by providing a controlled and stable environment for vessels. The cushioning effect of fenders minimizes the risk of vessel misalignment, erratic movements, and collisions, ensuring smooth and efficient berthing procedures. This results in reduced berthing time, improved vessel turnaround, and increased operational throughput.

- Longevity and Durability:

Port and harbor fenders are designed to withstand the demanding marine environment, including exposure to UV rays, saltwater, and abrasive substances. The use of high-quality rubber and polyurethane materials ensures the longevity and durability of fenders. Their resistance to weathering, chemicals, and impact ensures reliable performance and reduces the need for frequent fender replacements. By investing in long-lasting fenders, port authorities can significantly reduce maintenance costs associated with fender upkeep and replacements.

- Implementing Regular Maintenance Practices:

While port and harbor fenders offer durability and longevity, regular maintenance practices are essential to ensure their optimal performance. Routine inspections, cleaning, and lubrication help identify any signs of wear, damage, or deterioration. Timely repairs or replacements can be carried out, preventing the deterioration of fender performance and ensuring their continued effectiveness. By implementing proactive maintenance practices, port authorities can avoid costly breakdowns, extend the lifespan of fenders, and minimize overall maintenance expenses.

Conclusion:

Port and harbor fenders play a crucial role in reducing maintenance costs and operational downtime. By protecting port infrastructure, minimizing structural repairs, reducing vessel and equipment maintenance requirements, and streamlining berthing processes, these fenders contribute to cost savings and improved productivity. Bencros, as a leading manufacturer of rubber and polyurethane fenders, recognizes the importance of cost-effective solutions in the maritime industry. By investing in high-quality fender systems and implementing regular maintenance practices, port authorities can optimize their operations, enhance cost efficiency, and ensure the long-term sustainability of their ports and harbors.